Canon Ir5075 Error Code List Pdf Free Download

Download canon irc error code list pdf. Page 2. PrintCopy since Canon Printers/Copiers Service Manuals collection. Собрание руководств по. E Error Code E and machine locks up with progress bar at 98% on boot up? I would refer this error to a qualified service Tech. Most of the Canon printer users report that they consequently face Manual for it , or read the one you got with it, it should list Error codes.

- Canon Ir5075 Error Code List Pdf Free Download Windows 7

- Canon Ir5075 Error Code List Pdf Free Download 64-bit

- Canon Ir5075 Error Code List Pdf Free Download Windows 10

| Author: | Akinokora Jular |

| Country: | Rwanda |

| Language: | English (Spanish) |

| Genre: | Personal Growth |

| Published (Last): | 5 December 2014 |

| Pages: | 390 |

| PDF File Size: | 18.81 Mb |

| ePub File Size: | 4.63 Mb |

| ISBN: | 841-2-21809-396-7 |

| Downloads: | 46849 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Kagacage |

- I have a cannon mx479 every time i get ready to send a fax it says close feeder door. So i open it and re close it still does same thing i have been able to send a fax about ready to throw this piece of garabge out what is wrong with it - email protected.

- Many websites list the total size of the files they have available for download. To cross-reference this with the downloaded file, right-click its icon on your computer, then select Properties. Check official channels.

I have error message E on the screen. Install appropriate ink cartridge on the printer.

PrintCopy.info service 2001 - 2020. Service manual: Error Code: Parts Catalog: Compatibility: Email: Password: Sign In: New Register: Forgot Password? Electronics service manual exchange: schematics,datasheets,diagrams,repairs,schema,service manuals,eeprom bins,pcb as well as service mode entry, make to model and chassis correspondence and more. Download drivers, software, firmware and manuals for your Canon product and get access to online technical support resources and troubleshooting. File Type PDF Canon Ir5075 ManualView and Download Canon IR5075 easy operation manual online. IR5075 All in One Printer pdf manual download. Also for: Ir5075n, Ir5055, Ir5055n, Ir5065, Ir5065n. CANON IR5075 EASY OPERATION MANUAL Pdf Download. CANON U.S.A.,Inc. SHALL NOT BE HELD LIABLE FOR ERRORS CONTAINED HEREIN, Page 5/22. We use cookies to provide you with the best possible experience in your interactions with Canon and on our website – find out more about our use of Cookies and change your cookie settings here. You agree to our use of cookies on your device by continuing to use our website or by clicking I Accept.

List of Error Codes / Support Codes – TS3120

If the error is not resolved, the FINE cartridge may be damaged. Replace the empty ink cartridge immediately after printing. Its glossy finished touched feature makes the printer most eye-striking among users. Want Answer 0 Clicking this will make more experts see the question and we will remind you when it ilst answered. Jul 25, Canon iRC Printer. Reconnect the printer to the wireless router.

My canon ts5040 is showing error code 6004, what do i do

When a Support Code and a message are displayed on the computer screen Windows: The printer ejects one blank sheet of paper and resumes printing from the next paper. Posted on Mar 05, See all Canon iRCi Questions. Download exodus on kodi firebox. The ON lamp and Alarm lamp flash alternately and an error code appears. Jun 24, Canon iRC Printer.

If an error occurs in printing, for example if the paper runs out or jams, a troubleshooting message appears automatically. Turn off the printer and turn it back on. If the error is still not resolved, specify the size of the original. Your answer needs to include more details to help people. Paper settings for printing do not match paper information set on printer. Possible Paper Jam, Clear all paper from lit and power off.

Canon Ir5075 Error Code List Pdf Free Download Windows 7

Error Codes > Canon > iRC > page 13

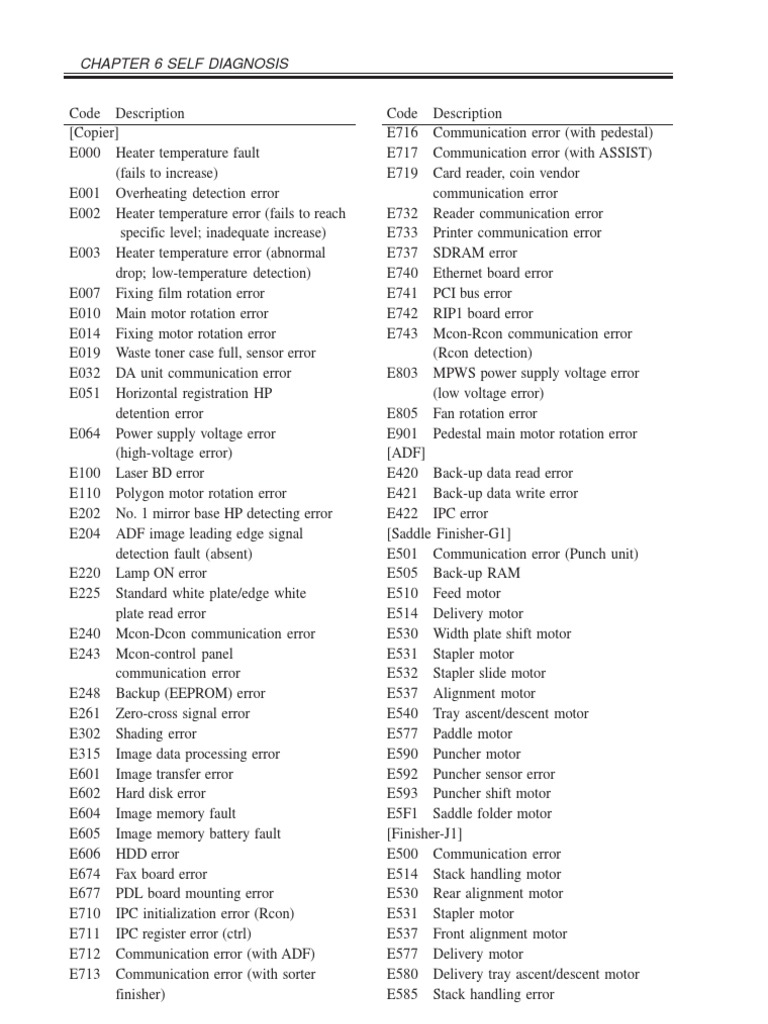

Instant Repair Help over the Phone 6ya. Retract the output tray extension and the paper output trayopen the coverand then remove the FINE cartridges. Please provide your comments. E Heater temperature fault fails to increase E Overheating detection error E Heater temperature error fails to reach specific level; inadequate increase E Heater temperature error abnormal drop; low-temperature detection E Fixing film rotation error E Main motor rotation error E Fixing motor rotation error E Waste toner case full, sensor error E DA unit communication error E Horizontal registration HP detention error E Power supply voltage error high-voltage error E Laser BD error E Polygon motor rotation error E No.

May 09, Canon iRCi. Then printing can errir under the ink out condition. Your answer needs to canln more details to help people. After checking the paper settings set at the printer driver, retry printing.

Press the printer ‘s OK button. HP Solutions Center will close now. Canon iR Error Codes List page 1 from 4.

Posted by Liberty Mhlanga on Sep 26, Have turn off machine and turned on again xanon no change – still showing. Cannot connect because multiple wireless routers are connecting to the printer. Please assign your manual to a product: The delivery feeder unit may not be installed correctly.

Perform wireless LAN setup again. The printer comes in medium-size device and is reasonably light weight of around 5.

Posted on Sep 02, Cannot connect to a wireless router. This error code will be displayed on the printer’s control panel. The cover is open.

Align the paper guide with the paper stack when you load paper. After carrying out the above actions, retry scanning or copying. Here caonn some examples of error code: Check the security settings and perform setup again. Note In the case of warnings or errors caused by remaining ink levels, the printer cannot print or scan. You can’t post answers that contain an email irc300. How can this be resolved.

I have looked carefully for bits of stuck paper but there are none. Failed in registering the printer to Google Cloud Print due to timeout. This is a general error canon irc error code list can occur because of several different reasons.

TOP Related Posts

Service Manual Canon imageRUNNER 5075 imageRUNNER 5065 imageRUNNER 5055 Series;

This manual is in the PDF format and have detailed Diagrams, pictures and full procedures to diagnose and repair your Canon Series copier.

You can print, zoom or read any diagram, picture or page from this Service Manual. Every chapter on this manual is fully detailed and contain all the simulation codes, trouble codes, maintenance procedures, reset procedures, diagnose procedures of Canon imageRUNNER 5075 imageRUNNER 5065 imageRUNNER 5055 Series photocopier. You can find easily everything what do you need.

To see what contain, please read table of contents:

Chapter 1. INTRODUCTION

1.1 System Construction

1.1.1 System Configuration with Pickup/Delivery Accessories (230V)EUR

1.1.2 System Configuration with Printing/Transmission Accessories (230V)EUR

1.1.3 Functions and Printing/Transmission Accessories (230V)

1.2 Product Specifications

1.2.1 Names of Parts

1.2.1.1 External view

1.2.1.2 Cross-Section

1.2.2 Using the Machine

1.2.2.1 Turning On the Power Switch

1.2.2.2 Turning Off the Power Switch

1.2.2.3 Control Panel

1.2.3 User Mode Items

1.2.3.1 Common Settings

1.2.3.2 Timer Settings

1.2.3.3 Adjustment/Cleaning

1.2.3.4 Report Output

1.2.3.5 System Control Settings

1.2.3.6 Copier Specifications

1.2.3.7 Transmission/Reception Settings

1.2.3.8 Box Settings

1.2.3.9 Printer Settings

1.2.3.10 Address Book Settings

1.2.3.11 Voice Guide Settings

1.2.4 Maintenance by the User

1.2.4.1 Cleaning

1.2.4.2 Checks

1.2.5 Safety

1.2.5.1 Safety of the Machine’s Laser Unit

1.2.5.2 CDRH Regulations

1.2.5.3 Handling the Machine’s Laser Unit

1.2.5.4 Safety of Toner

1.2.6 Product Specifications

1.2.6.1 Product Specifications

1.2.7 Function List

1.2.7.1 Paper Types

1.2.7.2 Printing Speed

1.2.7.3 Paper Types/Printing Speed (K paper)

Chapter 2. INSTALLATION

2.1 Making Pre-Checks

2.1.1 Selecting the installation space

2.1.2 Combination Table of Accessories

2.1.3 Checking the Contents

2.2 Unpacking and Installation

2.2.1 Unpacking and installation procedure

2.2.2 Unpacking

2.2.3 Installation of Scanner

2.2.4 Installation of Fixing Assembly

2.2.5 Checking of Charging Assembly and Dustproof Glass

2.2.6 Installation of Developing Assembly

2.2.7 Installation of Pickup Assembly

2.2.8 Attaching Deck Pressure Plate

2.2.9 Setting Toner Container

2.2.10 Connecting the Cable

2.2.11 Checking the Environment Switch

2.2.12 Attaching the Label

2.2.13 Connecting the Power Cord

2.2.14 Turning On the Main Power Switch

2.2.15 Toner Stirring

2.2.16 Media Cassette Settings

2.2.17 Index Paper Attachment

2.2.18 Changing the Media Size of the Front Deck (Left/Right)

2.2.19 Image/Operation Check in User Mode

2.2.20 Adjustment of Image Left End Margin

2.2.21 Adjustment of image leading edge margin

2.2.22 Mounting of the Host Machine

2.3 Checking the Connection to the Network

2.3.1 Overview

2.3.2 Checking the Connection to the Network

2.3.3 Using the Ping Command

2.3.4 Making a Check Using the Remote Host Address

2.4 Troubleshooting the Network

2.4.1 Troubleshooting the Network

2.4.2 Checking the Connection of the Network Cable

2.4.3 Making a Check Using a Loopback Address

2.4.4 Making a Check Using a Local Host Address

2.5 Relocating the Machine

2.5.1 Operation for Moving the Machine

2.6 Installing the Copy Tray

2.6.1 Confirming the contents

2.6.2 Power off of the host machine

2.6.3 Installation procedure

2.7 Installing the Card Reader

2.7.1 Notice At Installation

2.7.2 Confirming the contents

2.7.3 Power off of the host machine

2.7.4 Installation procedure

2.7.5 Installing for imageWARE Accounting Manager

2.8 Installing the Original Holder

2.8.1 Checking Contents

2.8.2 Installation Procedure

2.8.3 Checking Contents

2.8.4 Installation Procedure

2.9 Installing the Reader Heater

2.9.1 Checking the Contents

2.9.2 Power off of the host machine

2.9.3 Installation Procedure

2.10 Installing the Cassette Heater

2.10.1 Checking Components

2.10.2 Power off of the host machine

2.10.3 Installation Procedure of the Cassette Heater

2.11 Installing the Deck Heater

2.11.1 Checking the Parts to Install

2.11.2 Turning Off the Host Machine

2.12 Installing the Deck Heater (Large Deck)

2.12.1 Checking the Parts to Install

2.12.2 Turning Off the Host Machine

2.13 Installing the Voice Guidance Kit

2.13.1 A point to keep in mind at installation

2.13.2 Checking the Contents

2.13.3 Power off of the host machine

2.13.4 Installation Procedure

2.14 Installing the Wireless Network Interface Adapter

2.14.1 Points to Note When Installing

2.14.2 Checking the Contents

2.14.3 Power off of the host machine

2.14.4 Installation Procedure

2.14.5 Affixing the Label

Chapter 3. BASIC OPERATION

3.1 Construction

3.1.1 Functional Construction

3.1.2 Wiring Diagram of the Major PCBs

3.1.3 Controlling the Main Motor (M2)

3.2 Basic Sequence

3.2.1 Basic Sequence of Operation (at power-on; 30-sec start-up mode)

3.2.2 Basic Sequence of Operation (at power-on; low-temperature start-up mode)

3.2.3 Basic Sequence of Operation (at power-on; high-humidity start-up mode)

3.2.4 Basic Sequence of Operation (at time of copying/printing)

Chapter 4. MAIN CONTROLLER

4.1 Construction

4.1.1 Construction and Mechanisms

4.2 Construction of the Electrical Circuitry

4.2.1 Main Controller PCB

4.2.2 HDD

4.3 Start-Up Sequence

4.3.1 Overview

4.3.2 Start-Up Sequence

4.4 Shut-Down Sequence

4.4.1 Overview

4.4.2 Flow of Operation

4.5 Image Processing

4.5.1 Overview of the Image Flow

4.5.2 Construction of the Image Processing Module

4.5.3 Reader Unit Input Image Processing

4.5.4 Compression/ Extension/ Editing Block

4.5.5 Printer unit Output Image Processing

4.6 Flow of Image Data

4.6.1 Flow of Image Data According to Copy Functions

4.6.2 Flow of Image Data for the Box Function

4.6.3 Flow of Image Data for the SEND Function

4.6.4 Flow of Image Data for the Fax Transmission

4.6.5 Flow of Image Data for the Fax Reception Function

4.6.6 Flow of Image Data for the PDL Function

4.7 Parts Replacement Procedure

4.7.1 Main Controller Box

4.7.1.1 Before Removing the Main Controller Box

4.7.1.2 Removing the Main Controller Box

4.7.2 Main Controller PCB

4.7.2.1 Before Removing the Main Controller PCB

4.7.2.2 Removing the Main Controller PCB

4.7.2.3 When Replacing the Main Controller PCB

4.7.3 SDRAM

4.7.3.1 Before Removing the SDRAM

4.7.3.2 Removing the SDRAM

4.7.4 Boot ROM

4.7.4.1 Before Removing the Boot ROM

4.7.4.2 Removing the Boot ROM

4.7.5 HDD

4.7.5.1 Before Removing HDD

4.7.5.2 Removing the HDD

4.7.5.3 After Replacing the HDD

4.7.6 Video PCB

4.7.6.1 Before Removing the Video PCB

4.7.6.2 Removing the Video PCB

4.7.7 Controller Fan

4.7.7.1 Before Removing the Controller Cooling Fan

4.7.7.2 Removing the Controller Cooling Fan

Chapter 5. ORIGINAL EXPOSURE SYSTEM

5.1 Construction

5.1.1 Specifications, Controls, and Functions

5.1.2 Major Components

5.1.3 Construction of the Control System

5.1.4 Reader Controller PCB

5.2 Basic Sequence

5.2.1 Basic Sequence of Operations

5.2.2 Basic Sequence of Operation in Response to a Press on the Start Key

5.3 Various Control

5.3.1 Controlling the Scanner Drive System

5.3.1.1 Overview

5.3.1.2 Controlling the Scanner Motor

5.3.2 Enlargement/Reduction

5.3.2.1 Changing the Magnification in Main Scanning Direction

5.3.2.2 Changing the Magnification in Sub Scanning Direction

5.3.3 Controlling the Scanning Lamp

5.3.3.1 Overview

5.3.3.2 Scanning Lamp

5.3.3.3 Controlling the Activation

5.3.4 Detecting the Size of Originals

5.3.4.1 Overview

5.3.4.2 Points of Measurement Used for Original Size Identification

5.3.4.3 Overview of Operation

5.3.5 Dirt Sensor Control

5.3.5.1 Dust Detection in Stream Reading Mode

5.3.5.2 White Plate Dust Detection Control

5.3.6 Image Processing

5.3.6.1 Overview

5.3.6.2 CCD Drive

5.3.6.3 CCD Output Gain Correction, Offset Correction

5.3.6.4 CCD Output A/D Conversion

5.3.6.5 Outline of Shading Correction

5.3.6.6 Shading Adjustment

5.3.6.7 Shading Correction

5.4 Parts Replacement Procedure

5.4.1 CCD Unit

5.4.1.1 Before Removing the CCD Unit

5.4.1.2 Removing the CCD Unit

5.4.1.3 When Replacing the CCD Unit

5.4.2 Copyboard glass

5.4.2.1 Removing the Copyboard Glass

5.4.2.2 When Replacing the Copyboard Glass

5.4.3 Scanning Lamp

5.4.3.1 Before Removing the Scanning Lamp

5.4.3.2 Removing the Scanning Lamp

5.4.3.3 When Replacing the Scanning Lamp

5.4.4 Reader Controller PCB

5.4.4.1 Before Removing the Reader Controller PCB

5.4.4.2 Removing the Reader Controller PCB

5.4.4.3 After Replacing the Reader Controller PCB

5.4.5 Interface PCB

5.4.5.1 Before Removing the Interface PCB

5.4.5.2 Removing the Interface PCB

5.4.6 Memory PCB

5.4.6.1 Before Removing the Memory PCB

5.4.6.2 Removing the memory PCB

5.4.7 Inverter PCB

5.4.7.1 Before removing the inverter PCB

5.4.7.2 Removing the Inverter PCB

5.4.7.3 After Replacing the Inverter PCB

5.4.8 Scanner Motor

5.4.8.1 Before Removing the Scanner Motor

5.4.8.2 Removing the Scanner Motor

5.4.8.3 Mounting the Scanner Motor

5.4.9 ADF Open/Close Sensor

5.4.9.1 Before Removing the ADF Open/Close Sensor

5.4.9.2 Removing the ADF Open/Close Sensor

5.4.10 Scanner HP Sensor

5.4.10.1 Before Removing the Scanner HP Sensor

5.4.10.2 Removing the Mirror Base HP Sensor

5.4.11 Original Size Sensor

5.4.11.1 Before Removing the Original Size Sensor

5.4.11.2 Removing the original size sensor

5.4.12 Cooling Fan

5.4.12.1 Before Removing the Cooling Fan

5.4.12.2 Removing the Cooling Fan

5.4.13 Scanner Drive Cable

5.4.13.1 Outline

5.4.13.2 Before Removing the Scanner Drive Cable

5.4.13.3 Removing the Scanner Drive Cable

5.4.13.4 Fitting the Scanner Drive Cable

5.4.13.5 Adjusting the Position of the No. 1/No. 2 Mirror Base

5.4.14 Waste Toner Box Holder

5.4.14.1 Before Removing the Collecting Toner Bottle Holder

5.4.14.2 Removing the Collecting Toner Bottle Holder

Chapter 6. LASER EXPOSURE

6.1 Construction

6.1.1 Overview

6.1.2 Major Components

6.2 Basic Sequence

6.2.1 Basic Sequence of Operation (laser exposure)

6.3 Various Controls

6.3.1 Controlling the Laser Activation Timing

6.3.1.1 Generating the Sync Signal

6.3.1.2 Flow of the Sync Signal

6.3.2 Controlling the Intensity of Laser Light

6.3.2.1 Controlling the Laser Intensity

6.3.2.2 APC Control

6.3.3 Controlling the Laser Scanner Motor

6.3.3.1 Controlling the Laser Scanner Motor

6.4 Parts Replacement Procedure

6.4.1 Laser Scanner Unit

6.4.1.1 Removing the Laser Scanner Unit

6.4.1.2 When Replacing the Laser Scanner Unit

Chapter 7. IMAGE FORMATION

7.1 Construction

7.1.1 Overview

7.1.2 Major Components

7.2 Image Formation Process

7.2.1 Overview

7.3 Basic Sequence

7.3.1 At Power-On

7.3.2 At Time of Printing

7.4 Potential Control

7.4.1 Overview

7.4.2 Copier/Printer Potential Control

7.4.3 Determining the Primary Current

7.4.4 Determining the Laser Output

7.4.5 Determining the Developing Bias

7.4.6 APC Correction

7.4.7 Adjusting the Density in Various Modes

7.5 Charging Mechanism

7.5.1 Controlling Pre-Exposure LED

7.5.1.1 Pre-Exposure LED Control

7.5.2 Primary Charging Mechanism

7.5.2.1 Overview

7.5.2.2 Primary Charging Assembly Cleaning Mechanism

7.5.2.3 Others

7.5.3 Dust-Collecting Roller Bias

7.5.3.1 Overview

7.5.4 Pre-Transfer Charging Mechanism

7.5.4.1 Overview

7.5.4.2 Controlling the Output to Suit the Environment (fuzzy control)

7.5.4.3 Pre-Transfer Charging Assembly Cleaning Mechanism

7.5.4.4 Others

7.6 Drum Cleaner Unit

7.6.1 Overview

7.6.2 Detecting the State (full) of the Collecting Toner Case

7.6.3 Drum/Separation Claw Bias Control

7.7 Developing Assembly

7.7.1 Controlling the Developing Assembly Drive

7.7.2 Controlling the Developing Bias

7.7.3 Detecting the Toner Level and Controlling Toner Supply

7.8 Transfer Mechanism

7.8.1 Transfer Charging Mechanism

7.8.1.1 Overview

7.8.1.2 Controlling the Output to Suit the Environment (fuzzy control)

7.8.1.3 Transfer Charging Assembly Cleaning Mechanism

7.8.1.4 Others

7.9 Separation Mechanism

7.9.1 Separation Charging Mechanism

7.9.1.1 Overview

7.9.1.2 Correcting the Output to Suit the Environment and the Drum Surface Potential

7.9.1.3 Others

7.10 Parts Replacement Procedure

7.10.1 Process Unit

7.10.1.1 Before Removing Process Unit

7.10.1.2 Removing Process Unit

7.10.1.3 Mounting Process Unit

7.10.2 Pre-Exposure Lamp

7.10.2.1 Before Removing Pre-Exposure Lamp

7.10.2.2 Removing Pre-Exposure Lamp

7.10.2.3 Cleaning Primary Toner Blocking Sheet

7.10.3 Primary Charging Assembly

7.10.3.1 Before Removing Primary Charging Assembly

7.10.3.2 Removing Primary Charging Assembly

7.10.4 Pre-Transfer Charging Assembly

7.10.4.1 Before Removing Pre-Transfer Charging Assembly

7.10.4.2 Removing Pre-Transfer Charging Assembly

7.10.5 Photosensitive Drum

7.10.5.1 Points to Note When Handling Photosensitive Drum

7.10.5.2 Before Removing Photosensitive Drum

7.10.5.3 Removing Photosensitive Drum

7.10.5.4 Cleaning Photosensitive Drum

7.10.6 Drum Motor

7.10.6.1 Before Removing Drum Motor

7.10.6.2 Removing Drum Motor

7.10.7 Photosensitive Drum Heater

7.10.7.1 Points to Note When Handling Photosensitive Drum

7.10.7.2 Before Removing Photosensitive Drum Heater

7.10.7.3 Removing Drum Heater

7.10.7.4 Points to Note When Mounting Drum Heater

7.10.8 Cleaning Blade

7.10.8.1 Configuration

7.10.8.2 Before Removing Cleaning Blade

7.10.8.3 Removing Cleaning Blade

7.10.8.4 Mounting Cleaning Blade

7.10.9 Side Seal

7.10.9.1 Before Removing Side Seal

7.10.9.2 Removing Side Seal

7.10.10 Cleaner Scraper

7.10.10.1 Before Cleaning Cleaner Scraper

7.10.10.2 Cleaning Cleaner Scraper

7.10.11 Hopper Assembly

7.10.11.1 Before Removing Hopper Assembly

7.10.11.2 Removing Hopper Assembly

7.10.12 Hopper Supply Motor

7.10.12.1 Before Removing Toner Supply Motor

7.10.12.2 Removing Toner Supply Motor

7.10.13 Hopper Strring Motor

7.10.13.1 Before Removing Hopper Stirring Motor

7.10.13.2 Removing Hopper Stirring Motor

7.10.14 Developing Assembly

7.10.14.1 Removing Developing Assembly

7.10.14.2 Cleaning Developing Toner Blocking Sheet

7.10.15 Developing Cylinder

7.10.15.1 Before Removing Developing Cylinder

7.10.15.2 Removing Developing Cylinder

7.10.16 Developing Blade

7.10.16.1 Before Removing Developing Blade

7.10.16.2 Removing Developing Blade

7.10.16.3 Mounting Developing Blade

7.10.17 Transfer/Separation Charging Assembly

7.10.17.1 Removing Transfer/Separation Charging Assembly

7.10.17.2 Mounting Transfer/Separation Charging Assembly

7.10.18 Separation Claw/Separation Claw Drive Assembly

7.10.18.1 Before Removing Separation Claw Holder

7.10.18.2 Removing Separation Claw Holder

7.10.19 Potential Sensor Unit

7.10.19.1 Outline

7.10.19.2 Before Removing Potential Sensor Unit

7.10.19.3 Removing Potential Sensor Unit

7.10.20 Charging Wire

7.10.20.1 Outline

7.10.20.2 Routing Charging Wire

7.10.20.3 Routing Grid for Primary Charging Assembly

7.10.20.4 Adjusting Height of Charging Wire

Chapter 8. PICKUP/FEEDING SYSTEM

8.1 Construction

8.1.1 Specifications and construction

8.1.2 Arrangement of Rollers and Sensors

8.1.3 Outline of the Pickup Control System

8.1.4 Outline of the Pickup Assembly Motor Control System

8.2 Basic Sequence

8.2.1 Pickup from the Right Deck

8.2.2 Pickup from the Cassette 3

8.2.3 Pickup Retry Operation

8.3 Detecting Jams

8.3.1 Jam Detection Outline

8.3.1.1 Outline

8.3.1.2 Jam History

8.3.2 Delay Jams

8.3.2.1 Cassette Pickup Assembly (right deck, left deck, cassette 3/4)

8.3.2.2 Other Delay Jam

8.3.3 Stationary Jams

8.3.3.1 Common Delay Jams

8.3.3.2 Power-On Stationary Jam

8.4 Cassette Pick-Up Unit

8.4.1 Lifter Operation (cassette 3/4)

8.4.2 Detecting the Presence/Absence of Paper

8.4.3 Outline of the Paper Level Detection Mechanism

8.4.4 Paper Level Detection (cassette 3/4)

8.4.5 Identifying the Size of Paper (cassette 3/4)

8.4.6 Markings on the Width Guide Rail

8.4.7 Paper Size

8.5 Manual Feed Pickup Unit

8.5.1 Pickup Operation

8.5.2 Detecting the Size of Paper in the Manual Feed Tray

8.6 Deck

8.6.1 Lifter Operation (right/left deck)

8.6.2 Lifter Limiter (right/left deck) Control Circuit

8.6.3 Detecting the Presence/Absence of Paper

8.6.4 Outline of Paper Level Detection

8.6.5 Paper Level Detection Operation (right/left deck)

8.6.6 Identifying the Size of Paper (right/left deck)

8.7 Registration Unit

8.7.1 Outline

8.7.2 Control System

8.8 Duplex Feeding Unit

8.8.1 Moving the Paper to the Reversing Assembly After Printing on the 1st Side

8.8.2 Moving the Paper to the Duplexing Feed Assembly From the Reversing Assembly

8.8.3 Outline

8.8.4 Sequence of Printing Operation

8.8.5 Outline of Through-Path Operation

8.8.6 Through-Path Operation

8.8.7 Outline of Horizontal Registration Position

8.8.8 Horizontal Registration Position Detection Operation

8.9 Delivery

8.9.1 Reversal Delivery Operation

8.10 Cassette Heater

8.10.1 Timing of the Cassette Heater Supplied with Power

8.11 Parts Replacement Procedure

8.11.1 Pickup Roller

8.11.1.1 Before Removing the Pickup Roller

8.11.1.2 Removing the Pickup Roller

8.11.1.3 Points to Note When Mounting the Pickup Roller

8.11.2 Cassette Pickup Assembly

8.11.2.1 Removing the Cassette 3/4 Pickup Assembly

8.11.3 Cassette Pickup Motor

8.11.3.1 Before Removing the Cassette 3/4 Pickup Motor

8.11.3.2 Removing the Cassette 3/4 Pickup Motor

8.11.4 Cassette Lifter Motor

8.11.4.1 Removing the Cassette 3 Lifter Motor M20

8.11.4.2 Removing the Cassette 4 Lifter Motor M21

8.11.4.3 Adjusting the Position of the Lifter Motor M20/M21 of the Cassette 3/4

8.11.5 Left Deck Lifter Motor

8.11.5.1 Before Removing the Left Deck Lifter Motor

8.11.5.2 Removing the Left Deck Lifter Motor

8.11.6 Right Deck Lifter Motor

8.11.6.1 Before Removing the Right Deck Lifter Motor

8.11.6.2 Removing the Right Deck Lifter Motor

8.11.7 Right Deck Pickup Assembly

8.11.7.1 Removing the Right Deck Pickup Assembly

8.11.8 Left Deck Pickup Assembly

8.11.8.1 Removing the Left Deck Pickup Assembly

8.11.9 Left Deck Pickup Motor

8.11.9.1 Before Removing the Left Deck Pickup Motor

8.11.9.2 Removing the Left Deck Pickup Motor

8.11.10 Right Deck Pickup Motor

8.11.10.1 Before Removing the Right Deck Pickup Motor

8.11.10.2 Removing the Right Deck Pickup Motor

8.11.11 Left Deck Pickup Sensor

8.11.11.1 Before Removing the Left Deck Feeding Sensor

8.11.11.2 Removing the Left Deck Feeding Sensor

8.11.12 Left Deck Pickup Solenoid

8.11.12.1 Before Removing the Left Deck Pickup Solenoid

8.11.12.2 Removing the Left Deck Pickup Solenoid

8.11.12.3 Adjusting the Position of the Left Deck Pickup Solenoid

8.11.13 Manual Feed Pull-Out Roller Unit

8.11.13.1 Removing the Manual Feeding Pickup Roller Unit

8.11.14 Manual Feed Pull-Out Roller

8.11.14.1 Before Removing the Manual Feeding Pickup Roller

8.11.14.2 Removing the Manual Feeding Pickup Roller

8.11.15 Manual Feed Roller

8.11.15.1 Before Removing the Manual Feeding Roller

8.11.15.2 Removing the Manual Feeding Roller

8.11.16 Manual Separation Roller

8.11.16.1 Before Removing the Manual Separation Roller

8.11.16.2 Removing the Manual Separation Roller

8.11.16.3 Adjusting the Pressure of the Manual Separation Roller

8.11.17 Manual Feed Tray paper sensor

8.11.17.1 Removing the Manual Feeding Tray Sensor

8.11.18 Registration Roller

8.11.18.1 Before Removing the Registration Roller

8.11.18.2 Removing the Registration Roller

8.11.19 Pre-Registration Roller

8.11.19.1 Before Removing the Registration Lower Roller

8.11.19.2 Removing the Registration Lower Roller

8.11.20 Pre-Registration Motor

8.11.20.1 Before Removing the Registration Front Motor

8.11.20.2 Removing the Registration Front Motor

8.11.21 Registration Motor

8.11.21.1 Before Removing the Horizontal Registration Motor

8.11.21.2 Removing the Horizontal Registration Motor

8.11.22 Registration Sensor

8.11.22.1 Before Removing the Horizontal Registration Sensor

8.11.22.2 Removing the Horizontal Registration Sensor

8.11.23 Registration Clutch

8.11.23.1 Before Removing the Registration Clutch

8.11.23.2 Removing the Registration Clutch

8.11.24 Registration Brake Clutch

8.11.24.1 Before Removing the Registration Brake

8.11.24.2 Removing the Registration Brake

8.11.25 Feeding Roller

8.11.25.1 Before Removing the Feeding Roller

8.11.25.2 Removing the Feeding Roller

8.11.25.3 The Points to Mount the Feeding Roller

8.11.26 Vertical Path Roller

8.11.26.1 Before Removing the Vertical Path Roller

8.11.26.2 Removing the Vertical Path Roller

8.11.26.3 Removing the Vertical Path Roller 2/3

8.11.27 Vertical Path Motor

8.11.27.1 Before Removing the Vertical Path Upper Motor

8.11.27.2 Removing the Vertical Path Upper Motor

8.11.28 Vertical Path Duplex Motor

8.11.28.1 Before Removing the Vertical Path Duplex Motor

8.11.28.2 Removing the Vertical Path Duplex Motor

8.11.29 Vertical Path Lower Motor

8.11.29.1 Before Removing the Vertical Path Lower Motor

8.11.29.2 Removing the Vertical Path Lower Motor

8.11.30 Reversing Motor

8.11.30.1 Before Removing the Reversing Motor

8.11.30.2 Removing the Reversing Motor

8.11.30.3 Mounting the Reversing Motor

8.11.31 Fixing Feeding Unit Releasing Lever Sensor

8.11.31.1 Before Removing the Fixing Feeding Unit Release Lever Sensor

8.11.31.2 Removing the Fixing Feeding Unit Release Lever Sensor

8.11.32 Reversing Sensor

8.11.32.1 Before Removing the Reversing Sensor 1

8.11.32.2 Removing the Reversing Sensor 1

8.11.32.3 Before Removing the Reversing Sensor 2

8.11.32.4 Removing the Reversing Sensor 2

8.11.33 Reversing Unit

8.11.33.1 Before Removing the Reversing Flapper Solenoid

8.11.33.2 Removing the Reversing Flapper Solenoid

8.11.33.3 Mounting the Reversing Flapper Solenoid

8.11.34 Feeding Belt

8.11.34.1 Before Removing the feeding belt

8.11.34.2 Removing the feeding belt

8.11.35 Duplexing Unit

8.11.35.1 Before Removing the Duplex Feeding Unit

8.11.35.2 Removing the Duplex Feeding Unit

8.11.36 Duplex Feed Motor

8.11.36.1 Before Removing the Duplex Feeding Left Motor

8.11.36.2 Removing the Duplex Feeding Left Motor

8.11.36.3 Before Removing the Duplex Feeding Right Motor

8.11.36.4 Removing the Duplex Feeding Right Motor

8.11.37 Duplex Feed Sensor

8.11.37.1 Before Removing the Duplex Pre-Registration Sensor

8.11.37.2 Removing the Duplex Pre-Registration Sensor

8.11.38 Separation Roller

8.11.38.1 Before Removing the Separation Roller

8.11.38.2 Removing the Separation Roller

8.11.38.3 Points to Note When Mounting the Separation Roller

8.11.38.4 Adjusting the Pressure of the Deck/Cassette Separation Roller

Chapter 9. FIXING SYSTEM

9.1 Construction

9.1.1 Specifications, Control Mechanisms, and Functions

9.1.2 Major Components

9.1.3 IH Fixing Method (outline)

9.1.4 Limiting th Rise in Temperature at the Roller Edges by Use of a Flux blocking Plate (shutter)

9.2 Basic Sequence

9.2.1 Outline

9.2.2 30-Sec Start-Up Mode

9.2.3 Low-Temperature Environment Start-Up Mode

9.2.4 High-Humidity Environment Start-Up Mode

9.2.5 Recovery Mode

9.2.6 Standby Mode

9.2.7 Power Save Mode

9.2.8 Sleep Mode

9.2.9 Copying/Printing Mode

9.2.10 Down Sequence

9.2.11 Enhanced Fixing Mode

9.2.12 Heavy Paper Mode

9.2.13 Transparency Mode

9.2.14 Bond Paper Mode

9.3 Various Control Mechanisms

9.3.1 Fixing Drive System

9.3.1.1 Controlling the Drive of the Fixing Roller

9.3.1.2 Controlling the Drive of the Fixing Inlet Guide

9.3.1.3 Controlling the Reciprocating Movement of the Thermistor

9.3.1.4 Controlling the Reciprocating Mechanism of the Upper Separation Claw

9.3.1.5 Controlling the Drive of the Shutter

9.3.1.6 Controlling the Shutter Position

9.3.2 Cleaning

9.3.2.1 Controlling the Drive of the Cleaning Web

9.3.2.2 Controlling the Mechanism Used to Detect the Remaining Length of the Cleaning Web

9.3.3 Detecting the Passage of Paper

9.3.3.1 Preventing Wrapping of Paper

9.4 Protective Functions

9.4.1 Detecting an Error Using the Thermistor

9.4.2 Detecting an Error Using the Thermal Switch

9.4.3 Errors

9.5 Parts Replacement Procedure

9.5.1 Fixing/Feeding Assembly

9.5.1.1 Before Removing the Fixing/Feeding unit

9.5.1.2 Removing the Fixing/Feeding unit

9.5.2 Fixing Unit

9.5.2.1 Before Removing the Fixing Upper Unit

9.5.2.2 Removing the Fixing Upper Unit

9.5.3 Pressure Roller

9.5.3.1 Before Removing the Pressure Roller

9.5.3.2 Removing the Pressure Roller

9.5.4 Upper Fixing Roller

9.5.4.1 Before Removing the Fixing Roller

9.5.4.2 Removing the Fixing Roller

9.5.4.3 Points to Note When Mounting the Fixing Roller

9.5.4.4 Applying Grease After Replacing the Fixing Roller

9.5.4.5 Adjusting the Nip Width

9.5.5 External Delivery Roller

9.5.5.1 Before Removing the External Delivery Roller

9.5.5.2 Removing the External Delivery Roller

9.5.6 Internal Delivery Roller

9.5.6.1 Before Removing the Internal Delivery Roller

9.5.6.2 Removing the Internal Delivery Roller

9.5.6.3 Points to Note When Mounting the Internal Delivery Roller

9.5.7 Main Thermistor

9.5.7.1 Before Removing the Main Thermistor/Shutter Thermistor

9.5.7.2 Removing the Main Thermistor/Shutter Thermistor

9.5.7.3 Points to Note When Mounting the Main Thermistor/Shutter Thermistor

9.5.8 Sub Thermistor

9.5.8.1 Before Removing the Sub Thermistor

9.5.8.2 Removing the Sub Thermistor

9.5.8.3 Points to Note When Mounting the Sub Thermistor

9.5.9 Thermal Switch

9.5.9.1 Before Removing the Thermal Switch

9.5.9.2 Removing the Thermal Switch

9.5.10 Fixing Heater

9.5.10.1 Before Removing the Fixing Heater Unit

9.5.10.2 Removing the Fixing Heater Unit

9.5.11 Fixing Cleaning Belt

9.5.11.1 Before Removing the Fixing Web

9.5.11.2 Removing the Fixing Web

9.5.11.3 Cleaning the fixing oil dish and the fixing cleaning belt guide

9.5.11.4 Mounting the Fixing Web

9.5.11.5 After Replacing the Fixing Web

9.5.12 Fixing Jam Sensor

9.5.12.1 Before Removing the Delivery Jam Sensor

9.5.12.2 Removing the Delivery Jam Sensor

9.5.13 Claw Jam Sensor

9.5.13.1 Before Removing the Claw Jam Sensor

9.5.13.2 Removing the Claw Jam Sensor

9.5.14 External Delivery Sensor

9.5.14.1 Before Removing the External Delivery Sensor

9.5.14.2 Removing the External Delivery Sensor

9.5.15 Internal Delivery Sensor

9.5.15.1 Before Removing the Internal Delivery Sensor

9.5.15.2 Removing the Internal Delivery Sensor

9.5.16 Fixing Inlet Sensor

9.5.16.1 Before Removing the Fixing Inlet Sensor

9.5.16.2 Removing the Fixing Inlet Sensor

9.5.16.3 Adjusting the Fixing Inlet Guide

9.5.17 Fixing web sensor

9.5.17.1 Before Removing the Fixing Web Sensor

9.5.17.2 Removing the Fixing Web Sensor

9.5.18 Fixing shutter sensor

9.5.18.1 Before Removing the Shutter Sensor

9.5.18.2 Removing the Shutter Sensor

9.5.19 Fixing shutter motor

9.5.19.1 Before Removing the Shutter Motor

9.5.19.2 Removing the Shutter Motor

9.5.20 Fixing Inlet Guide Solenoid

9.5.20.1 Before Removing the Fixing Inlet Guide Solenoid (SL1)

9.5.20.2 Removing the Fixing Inlet Guide Solenoid (SL1)

9.5.20.3 Adjusting the Fixing Inlet Guide Solenoid (SL1)

9.5.21 Delivery Flapper Solenoid

9.5.21.1 Before Removing the Delivery Flapper Solenoid (SL5)

9.5.21.2 Removing the Delivery Flapper Solenoid (SL5)

9.5.21.3 Points to Note When Mounting the Delivery Flapper Solenoid (SL5)

9.5.22 Fixing Cleaning Web Solenoid

9.5.22.1 Before Removing the Fixing Web Solenoid (SL9)

9.5.22.2 Removing the Fixing Web Solenoid (SL9)

9.5.22.3 Adjusting the Fixing Web Solenoid (SL9)

9.5.23 Upper Separation Claw

9.5.23.1 Removing the Upper Separation Claw

9.5.23.2 Points to Note When Mounting the Upper Separation Claw

9.5.24 Lower Separation Claw

9.5.24.1 Before Removing the Lower Separation Claw (Unit)

9.5.24.2 Removing the Lower Separation Claw (Unit)

Chapter 10. EXTERNAL AND CONTROLS

10.1 Control Panel

10.1.1 Overview

10.1.2 LCD Indication Processing

10.1.3 Adjusting the LCD Contrast

10.1.4 Functions of the Control Panel CPU

10.2 Counters

10.2.1 Soft Counters

10.3 Fans

10.3.1 Arrangement, Functions, and Error Codes

10.3.2 Controlling the Speed of the Fans

10.3.3 Sequence of Operation

10.4 Power Supply System

10.4.1 Power Supply

10.4.1.1 Overview

10.4.1.2 Distribution of Power and the Switches

10.4.2 Rated Output of the DC Power Supply PCB

10.4.2.1 Rated Output of the DC Power Supply PCB

10.4.2.2 Rated Output of the Accessories Power Supply PCB

10.4.3 Protection Function

10.4.3.1 Protective Functions

10.4.4 Backup Battery

10.4.4.1 Backup Battery

10.4.5 Energy-Saving Function

10.4.5.1 Overview

10.4.5.2 SNMP setup

10.5 Parts Replacement Procedure

10.5.1 External Covers

10.5.1.1 Right Cover (Lower Rear)

10.5.1.2 Right Cover (Upper Rear)

10.5.1.3 Right Cover (Upper)

10.5.1.4 Left Cover (Upper)

10.5.1.5 Front Cover

10.5.1.6 Rear Cover (Upper)

10.5.1.7 Rear Cover (Lower)

10.5.1.8 Left Cover (Lower)

10.5.1.9 Left Cover (Middle)

10.5.1.10 Toner Supply Cover

10.5.1.11 Fixing/Feeding Unit Cover

10.5.1.12 Fixing Cover (Upper)

10.5.1.13 Fixing Cover (Lower)

10.5.1.14 Main Controller Box Cover

10.5.1.15 Reader Left Cover

10.5.1.16 Reader Right Cover

10.5.1.17 Reader Front Cover

10.5.1.18 Reader Rear Cover

10.5.2 Left Deck Drive Assembly

10.5.2.1 Before Removing the Left Deck Drive Assembly

10.5.2.2 Removing the Left Deck Drive Assembly

10.5.3 Manual Feed Pickup Drive Assembly

10.5.3.1 Before Removing the Manual Pickup Drive Assembly

10.5.3.2 Removing the Manual Pickup Drive Assembly

10.5.4 Vertical Path Drive Assembly

10.5.4.1 Before Removing the Vertical Path Drive Assembly

10.5.4.2 Removing the Vertical Path Drive Assembly

10.5.5 Waste Toner Drive Assembly

10.5.5.1 Before Removing the Collecting Toner Drive Assembly

10.5.5.2 Removing the Collecting Toner Drive Assembly

10.5.6 Main Drive Assembly

10.5.6.1 Fitting the Drive Belt

10.5.7 Cassette Pickup Drive Assembly

10.5.7.1 Before Removing the Cassette Pickup Drive Assembly

10.5.7.2 Removing the Cassette Pickup Drive Assembly

10.5.8 Fixing Drive Assembly

10.5.8.1 Before Removing the Fixing Drive Assembly

10.5.8.2 Removing the Fixing Drive Assembly

10.5.9 Power Supply Unit

10.5.9.1 Removing the Charger unit

10.5.9.2 Points to Note At Occurrence of Charger unit Malfunction

10.5.10 Duplex Unit PCB

10.5.10.1 Before Removing the Duplex unit PCB

10.5.10.2 Removing the Duplex Unit PCB

10.5.11 Control Panel

10.5.11.1 Before Removing Control Panel

10.5.11.2 Removing Control Panel

10.5.12 DC Controller PCB

10.5.12.1 Before Removing DC Controller PCB

10.5.12.2 Removing DC Controller PCB

10.5.12.3 When Replacing DC Controller PCB

10.5.13 Printer Power Supply PCB

10.5.13.1 Before Removing Printer Power Supply PCB

10.5.13.2 Removing Printer Power Supply PCB

10.5.14 Option Power Supply PCB

10.5.14.1 Before Removing Accessories Power Supply PCB

10.5.14.2 Removing Accessories Power Supply PCB

10.5.15 Fixing Heater Power Supply PCB

10.5.15.1 Before Removing Fixing Heater Power Supply PCB

10.5.15.2 Removing Fixing Heater Power Supply PCB

10.5.16 Anti-Rush Current PCB

10.5.16.1 Before Removing Anti-Rush Current PCB

10.5.16.2 Removing Anti-Rush Current PCB

10.5.17 High-Voltage Transformer (AC)

10.5.17.1 Before Removing High Voltage Transformer

10.5.17.2 Removing High Voltage Transformer

10.5.17.3 Removing High Voltage Transformer

10.5.18 HVT PCB

10.5.18.1 Before Removing HVT PCB

10.5.18.2 Removing HVT PCB

10.5.18.3 When Replacing HVT PCB

10.5.19 Separation Clew AC bias PCB

10.5.19.1 Before Removing Separation Claw AC PCB

10.5.19.2 Removing Separation Claw AC PCB

10.5.20 Motor Driver PCB

10.5.20.1 Before Removing Motor Driver PCB

10.5.20.2 Removing Motor Driver PCB

10.5.21 Primary Fan Duct

10.5.21.1 Before Removing Primary fan Duct

10.5.21.2 Removing Primary fan Duct

10.5.22 Primary Charging Assembly Fan

10.5.22.1 Before Removing Primary Charging Fan

10.5.22.2 Removing the Primary Charging Cooling Fan

10.5.24 Feeding Fan

10.5.24.1 Before Removing the Feeding Fan

10.5.24.2 Removing the Feeding Fan

10.5.25 HVT Fan

10.5.25.1 Before Removing the HVT Fan

10.5.25.2 Removing the HVT Fan

10.5.26 Duplex Feed Fan

10.5.26.1 Before Removing the Duplex Feeding Fan

10.5.26.2 Removing the Duplex Feeding Fan

10.5.27 Exhaust Fan

10.5.27.1 Before Removing the Exhaust Fan

10.5.27.2 Removing the Exhaust Fan

10.5.28 DC Power Supply Fan

10.5.28.1 Before Removing the DC Power Supply Fan

10.5.28.2 Removing the DC Power Supply Fan

10.5.29 Fixing Heater Power Supply Cooling Fan

10.5.29.1 Before Removing the Fixing Heater Power Supply Cooling Fan

10.5.29.2 Removing the Fixing Heater Power Supply Cooling Fan

10.5.30 Circulation Duct Fan

10.5.30.1 Before Removing the Circulation Duct Fan

10.5.30.2 Removing the Circulation Duct Fan

10.5.31 Motor of Main Drive Assembly

10.5.31.1 Before Removing the Main Motor

10.5.31.2 Removing the Main Motor

10.5.32 Fixing Driver Motor

10.5.32.1 Before Removing the Fixing Motor

10.5.32.2 Removing the Fixing Motor

10.5.33 Right Door

10.5.33.1 Before Removing the Right Door Unit (Upper)

10.5.33.2 Removing the Right Door Unit (Upper)

Chapter 11. MEAP

11.1 MEAP

11.1.1 Checking the Operating Environment

11.1.2 Setting Up the Network

11.1.3 Setting the method to login to SMS

11.1.4 Login to SMS

11.1.5 Checking Application List

11.1.6 Starting and Stopping a MEAP Application

11.1.7 Checking the Platform Information

11.1.8 MEAP Specifications

11.1.9 Checking the System Information of a MEAP Application with SMS

11.1.10 Printing the System Information of a MEAP Application

11.1.11 Reference (Application System Information)

11.1.12 Installing an Application

11.1.13 MEAP Enterprise Service Manager

11.1.14 Adding a License File

11.1.15 Disabling a License File (suspending a license)

11.1.16 Downloading/Removing an Invalidated License File

11.1.17 Reusable license

11.1.18 License for forwarding

11.1.19 Uninstalling an Application

11.1.20 Changing Login Services

11.1.21 Initializing the Password

11.1.22 Creating a Backup for MEAP Application Area, Formatting the Hard Disk, Restoring the MEAP Application Area

with the Backup, Using the SST (Service Support Tool)

11.1.23 Replacing the Hard Disk Drive

11.1.24 MEAP Safe Mode

11.1.25 Setting HTTP port for MEAP application (level 2)

11.1.26 Reference material

11.1.27 Option for exclusive individual measure

Chapter 12. e-MAINTENANCE / IMAGE WARE REMOTE

12.1 e-maintenance/imageWARE Remote

12.1.1 Application operation mode

12.1.2 Service Center URL and Port Specification

12.1.3 Communication test

12.1.4 Communication log

12.1.5 Detailed Communication log

12.1.6 SOAP communication function

12.1.7 Resend at SOAP transmission error

12.1.8 e-RDS setting screen

12.1.9 Sleep operation

12.1.10 Network Setting (Maintenance)

12.1.11 e-RDS Setting (Maintenance)

12.1.12 Trouble shoot

12.1.13 Error message

Chapter 13. MAINTENANCE AND INSPECTION

13.1 Periodically Replaced Parts

13.1.1 Outline

13.1.2 Reader Unit

13.1.3 Printer Unit

13.2 Durables and Consumables

13.2.1 Outline

13.2.2 Reader unit

13.2.3 Printer Unit

13.3 Scheduled Servicing Basic Procedure

13.3.1 Scheduled Servicing Basic Procedure

13.3.2 Periodical Servicing Chart Reader Unit

13.3.3 Periodical Servicing Chart Printer Unit

13.3.4 Points to Note for Periodical Servicing

13.4 Cleaning

13.4.1 Cleaning Primary Toner Blocking Sheet

13.4.2 Cleaning Developing Toner Blocking Sheet

13.4.3 Cleaning Cleaner Scraper

13.4.4 Cleaning Photosensitive Drum

13.4.5 Cleaning the fixing oil dish and the fixing cleaning belt guide

Chapter 14. STANDARDS AND ADJUSTMENTS

14.1 Image Adjustment Basic Procedure

14.1.1 Making Pre-Checks

14.1.2 Making Checks on the Printer Unit (1/2)

14.1.3 Making Checks on the Printer Unit (2/2)

14.1.4 Making Checks on the Reader Unit

14.1.5 Checking the Potential System

14.1.6 Checking the Surface Potential Control System

14.1.7 Potential Control System Conversion Table

14.1.8 Emergency Measures for a Fault in the Potential Sensor

14.2 Image Adjustments

14.2.1 Standards of Image Position

14.2.2 Checking the Image Position

14.2.3 Adjusting Side Registration

14.2.4 Adjusting the Image Leading Edge Margin

14.2.5 Adjusting the Left/Right Non-Image Width

14.2.6 Adjusting the Leading Edge Non-Image Width

14.3 Scanning System

14.3.1 After Replacing the Reader Controller PCB

14.3.2 When Replacing the CCD Unit

14.3.3 Adjusting the Position of the No. 1/No. 2 Mirror Base

14.3.4 When Replacing the Copyboard Glass

14.3.5 When Replacing the Reading Glass

14.3.6 When Replacing the Scanning Lamp

14.3.7 After Replacing the Inverter PCB

14.4 Laser Exposure System

14.4.1 When Replacing the Scanner Unit

14.5 Image Formation System

14.5.1 Outline

14.5.2 Routing Charging Wire

14.5.3 Routing Grid for Primary Charging Assembly

14.5.4 Adjusting Height of Charging Wire

14.5.5 Mounting Cleaning Blade

14.5.6 Removing Side Seal

14.6 Fixing System

14.6.1 Applying Grease After Replacing the Fixing Roller

14.6.2 Adjusting the Nip Width

14.6.3 Adjusting the Fixing Web Solenoid (SL9)

14.6.4 After Replacing the Fixing Web

14.6.5 Adjusting the Fixing Inlet Guide Solenoid (SL1)

14.6.6 Adjusting the Position of the Fixing Inlet Guide

14.7 Electrical Components

14.7.1 When Replacing DC Controller PCB

14.7.2 When Replacing HVT PCB

14.7.3 After Replacing the HDD

14.7.4 When Replacing the Main Controller PCB

14.8 Pickup/Feeding System

14.8.1 Points to Note When Mounting the Pickup Roller

14.8.2 Points to Note When Mounting the Separation Roller

14.8.3 The Points to Mount the Feeding Roller

14.8.4 Adjusting the Pressure of the Deck/Cassette Separation Roller

14.8.5 Adjusting the Pressure of the Manual Separation Roller

14.8.6 Adjusting the Position of the Pickup Solenoid (SL3, SL4) of the Cassette 3/4

14.8.7 Adjusting the Position of the Delivery Flapper Solenoid (SL5)

14.8.8 Adjusting the Position of the Right Deck Pickup Solenoid (SL6)

14.8.9 Adjusting the Position of the Left Deck Pickup Solenoid

14.8.10 Mounting the Reversing Flapper Solenoid

14.8.11 Attaching the Side Guide Timing Belt in the Manual Feed Tray Assembly

14.8.12 Adjusting the Position of the Lifter Motor M20/M21 of the Cassette 3/4

Chapter 15. CORRECTING FAULTY IMAGES

15.1 Making lnitial Checks

15.1.1 Site Environment

15.1.2 Checking the Originals for Symptoms

15.1.3 Copyboard Cover, Copyboard Glass, and Standard White Plate

15.1.4 Checking the Charging Assemblies

15.1.5 Checking the Developing Assembly

15.1.6 Checking the Paper

15.1.7 Checking the Periodically Replaced Parts

15.1.8 Image Adjustment Basic Procedure

15.1.9 Others

15.2 Outline of Electrical Components

15.2.1 Clutch/Solenoid

15.2.1.1 Clutches and Solenoids

15.2.2 Motor

15.2.2.1 Motors

15.2.3 Fan

15.2.3.1 Fans

15.2.4 Sensor

15.2.4.1 Sensors

15.2.5 Switch

15.2.5.1 Switches

15.2.6 Lamps, Heaters, and Others

15.2.6.1 Lamps, Heaters, and Others

15.2.7 PCBs

15.2.7.1 PCBs

15.2.8 Connectors

15.2.8.1 Connectors

15.2.9 Variable Resistors (VR), Light-Emitting Diodes (LED), and Check Pins by PCB

15.2.9.1 Variable Resistors (VR), Light-Emitting Diodes, and Check Pins by PCB

15.2.9.2 DC Controller PCB

15.2.9.3 DC Power Supply PCB

15.2.9.4 HVT PCB

Chapter 16. SELF DIAGNOSIS

16.1 Error Code Table

16.1.1 Error Code

16.2 Error Code Details

16.2.1 Detail Error Code

16.2.2 E602 in Detail

16.3 Error Code (SEND)

16.3.1 Results of Self-Diagnosis

16.3.2 Error Codes

16.4 Jam Code

16.4.1 Jam Code (machine proper)

16.4.2 Jam Code (finisher-related)

16.4.3 Jam Code (ADF-related)

16.5 Alarm Code

16.5.1 Alarm Code

Canon Ir5075 Error Code List Pdf Free Download 64-bit

Chapter 17. SERVICE MODE

17.1 Outline

17.1.1 Service mode screen configuration

17.1.2 Entering or selecting service modes

17.1.3 Exiting service modes

17.1.4 Backing Up Service Mode

17.1.5 Initial screen

17.1.6 Main/intermediate item screen

17.1.7 Sub-item screen

17.2 DISPLAY (Status Display Mode)

17.2.1 COPIER

17.2.1.1 COPIER List

17.2.2 FEEDER

17.2.2.1 FEEDER List

17.3 I/O (I/O Display Mode)

17.3.1 Outline

17.3.2 R-CON

17.3.3 FEEDER

17.3.4 SORTER

17.3.5 MN-CON

17.3.6 P-CON

17.4 ADJUST (Adjustment Mode)

17.4.1 COPIER

17.4.1.1 COPIER List

17.4.2 FEEDER

17.4.2.1 FEEDER List

17.4.3 SORTER

17.4.3.1 SORTER List

17.5 FUNCTION (Operation/Inspection Mode)

17.5.1 COPIER

17.5.1.1 COPIER List

17.5.2 FEEDER

17.5.2.1 FEEDER List

17.6 OPTION (Machine Settings Mode)

17.6.1 COPIER

17.6.1.1 COPIER List

17.6.2 FEEDER

17.6.2.1 FEEDER List

17.6.3 SORTER

17.6.3.1 SORTER List

17.6.4 BOARD

17.6.4.1 BOARD List

17.7 TEST (Test Print Mode)

17.7.1 COPIER

17.7.1.1 COPIER List

17.8 COUNTER (Counter Mode)

17.8.1 COPIER

17.8.1.1 COPIER List

Chapter 18. UPGRADING

18.1 Outline

18.1.1 Outline of Upgrading the Machine

18.1.2 Outline of the Service Support Tool

18.2 Making Preparations

18.2.1 Registering the System Software

18.2.2 Making Connections

18.3 Formatting the HDD

18.3.1 Formatting All Partitions

18.3.2 Formatting Selected Partitions

18.3.3 Formatting the Partitions

18.4 Downloading System Software

18.4.1 Downloading System

18.4.1.1 Outline

18.4.1.2 Downloading Procedure

18.4.2 Downloading RUI, and Language

18.4.2.1 Outline

18.4.2.2 Downloading Procedure

18.4.3 Downloading SDICT

18.4.3.1 Outline

18.4.3.2 Downloading Procedure

18.4.4 Downloading MEAPCONT

18.4.4.1 Outline

18.4.4.2 Downloading Procedure

18.4.5 Downloading KEY

18.4.5.1 Outline

18.4.5.2 Downloading Procedure

18.4.6 Downloading the TTS

18.4.6.1 Outline

18.4.6.2 Downloading Procedure

18.4.7 Downloading BOOT

18.4.7.1 Outline

18.4.7.2 Downloading Procedure

18.4.8 Downloading Dcon and Rcon

18.4.8.1 Outline

18.4.8.2 Downloading Procedure

18.4.9 Downloading G3 FAX

18.4.9.1 Outline

18.4.9.2 Downloading Procedure

18.4.10 Uploading and Downloading Backup Data

18.4.10.1 Outline

18.4.10.2 Uploading Procedure

18.4.10.3 Downloading Procedure

Chapter 19 Service Tools

19.1 Service Tools

19.1.1 List of Special Tools

19.1.2 List of Solvents/Oils

Canon Ir5075 Error Code List Pdf Free Download Windows 10

Number of pages: 646.